Project Scope

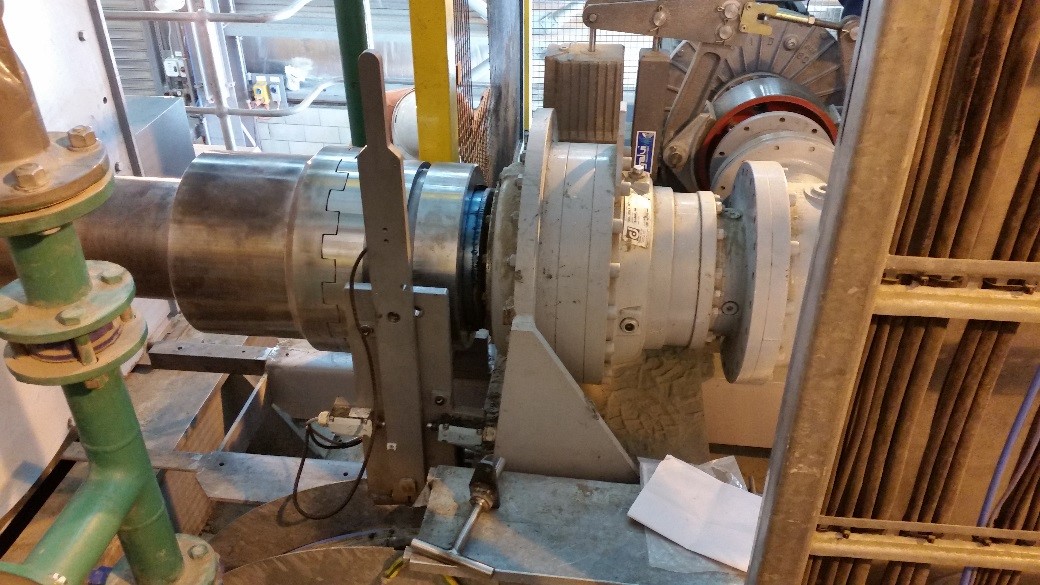

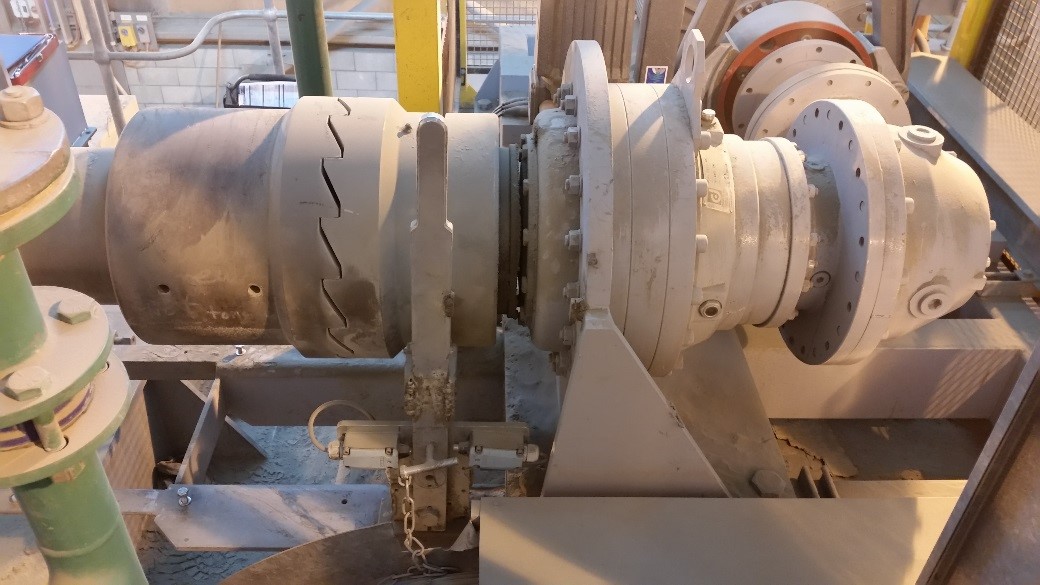

In the lead-up to a planned maintenance shutdown, Ingenia’s client urgently required an upgraded barring drive clutch system for their cement mill. The existing system, designed to disengage the barring drive when the cement mill main drive was operational, needed significant modifications. The client requested new clutch components with an updated profile and a more efficient clutch operation system to enhance performance.

Challenges

The project required a swift turnaround and a complex design to restrict the mill’s rotation in both forward and reverse, meeting the client’s specifications while improving the cement mill barring drive’s safety and functionality. After finalising the initial design, Ingenia conducted a comprehensive risk assessment, identifying the need for additional controls and interlocks to ensure compliance with AS4024 Safety of Machinery standards.

Ingenia then carried out detailed design work and liaised with the manufacturer to ensure efficient fabrication, confirming that the component could be produced within the required timeframe using available materials and tools.

Conclusion

After being designed by Ingenia and fabricated by a third-party contractor, the barring drive was installed and commissioned. The project was completed within a short timeframe, enabling installation and commissioning ahead of major works during the planned maintenance shutdown.

Positive feedback from Ingenia’s client advised that expectations had been met and exceeded yet again.

Our Services Discover how our engineering services can support your next project!